News and Blog

November 19, 2024

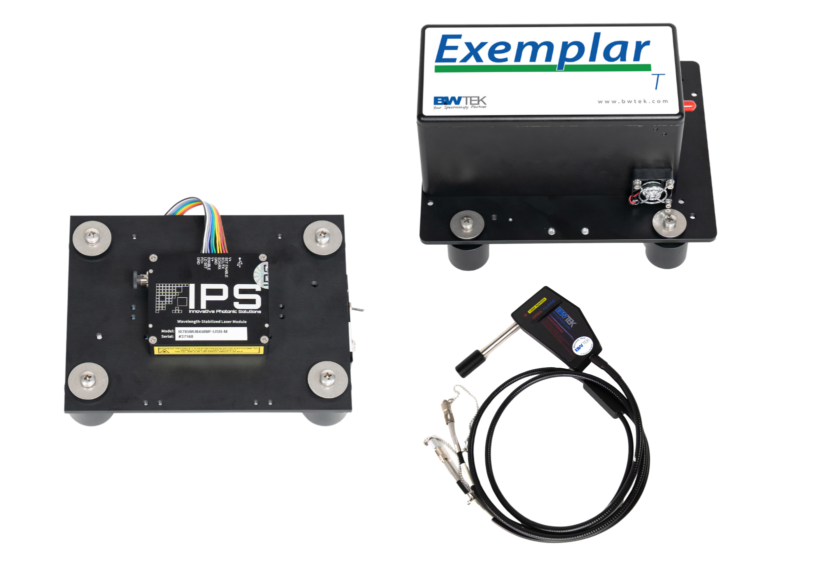

Metrohm and m-oem: Enabling Your Solution Together

Sharing Another Booth in Boston Metrohm USA and m-oem will be sharing a booth at the Materials Research Society’s Fall Exhibition. This will be the second time in 2 months that we are exhibiting together, the first being SciX just 3 weeks ago. We are excited about another opportunity to showcase the connection between the …

Keep Reading